CASE STUDY | In-process weld repair of ammonia converter with HotSense™ TOFD

Real-time evaluation of weld fills, during repair of an ammonia converter, using high-temperature TOFD

Key deliverables

- SonoInspec were able to conduct high-temperature TOFD whilst a weld was being repaired at elevated temperatures, and at various fill levels.

- Accurate, repeatable weld defect detection and sizing was enabled whilst repairing of the weld was conducted.

- Reduced maintenance time by undertaking inspection with no requirement to cool and reheat to preheat temperatures.

- Increased productivity by completing welding repair and inspection together.

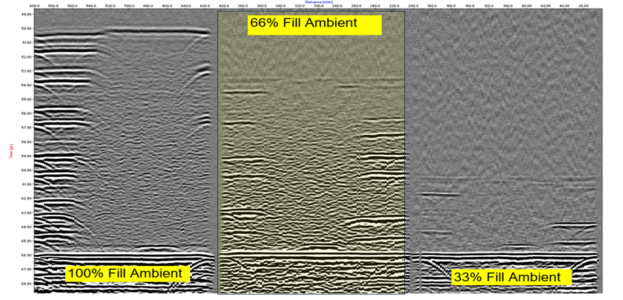

Figure 1: 5 MHz, 50 deg wedge combination scans of 3 validation blocks at each welded fill level at ambient temperature

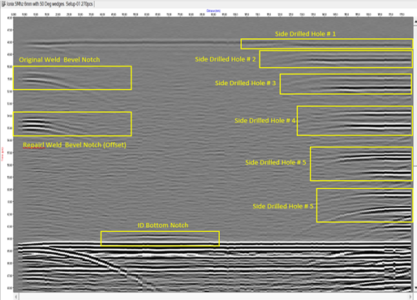

Figure 2: 5 MHz, 50 deg wedge B-scans of validation block at 100% fill level at (right) ambient temperature and (below) 185 °C, with all the artificial defects identified (yellow box)

Overview

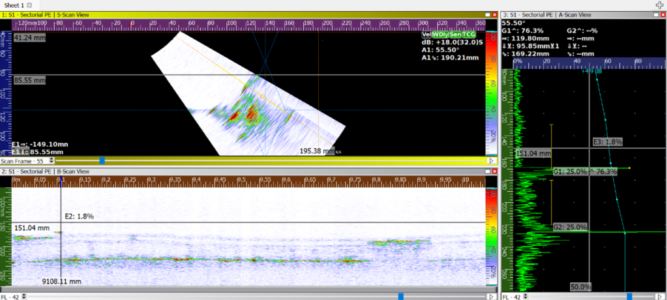

During a scheduled turnaround at a 4 year interval, multiple, major cracks were detected within the extremities of a shell-to-shell circumferential weld of an ammonia converter using ultrasonic methods – manual UT, TOFD and Phased Array (see Figure 3). The cracking was ID connected and propagating up to 50% of the through wall thickness. A subsequent repair campaign was launched, with SonoInspec, a global NDT service company specialising in non-intrusive inspections whilst plant is operational, undertaking TOFD examination at 66% partial, and 100% fill whilst at pre-heat temperatures of ~200 °C (400 °F) through the 120 mm (4.7”) thick steel wall to verify integrity of the repair in-situ.

Figure 3: Sectorial PE Phased Array UT scan with S-scan (top), B-scan (bottom) and A-scan (right) of the circumferential weld, showing indications of cracking damage

The Challenge

Ammonia converters operate at high-temperatures (200-400 °C / 390-750 °F) and pressures in the presence of hydrogen gas and catalyst, which can lead to damage mechanisms such as High-Temperature Hydrogen Attack (HTHA), nitriding and stress cracking in high-load areas such as around the basket.

Inspection and repairs are often preferred to be undertaken non-intrusively, from the outside shell to prevent the catalyst from being exposed to atmosphere and replaced.

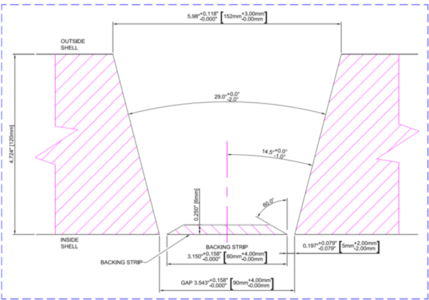

In this example, the repairs were executed to a custom weld design as shown in Figure 4, with a requirement for high-temperature Time Of Flight Diffraction (HT TOFD) examinations at both 66% and 100% weld fill, whilst at elevated temperatures, before the final post-weld heat treatment examination at ambient.

Before this could be accepted, validation blocks (Figure 5) were produced to aid the partial fill weld inspection at 200 °C, and verify the procedure. The blocks were manufactured with 33%, 66% and 100% weld fill and included 6 side-drilled hole (SDH), 3 mm ID surface EDM notch and artificial defects for validation. HT TOFD was required to be undertaken whilst hot.

Figure 4: Weld design

Figure 5: Validation blocks at varying weld fill levels

The Solution

To complete the TOFD examination at across the wide range of temperature with accuracy and reliability, SonoInspec used HotSense™ TOFD due to:

- The HotSense™ TOFD transducers operate over a wide temperature range -55 to +350 °C (-67 to +662 °F).

- Increased wear resistance and robust construction to offer longer probe life.

- Increased sensitivity to make reliable and accurate wall measurements even through the thick-walled components at elevated temperatures.

- Manufactured in compliance with international standards to easily fit directly into existing inspection procedures

- Quick to deploy, calibrate and begin taking measurements.

“We picked up a 3 mm EDM-notch at the far service crystal clear with HotSense™ TOFD, and with our regular probes we did not pick it up at all with the same setup [sic]. Actually, we can cover the full ASME block with HotSense™ TOFD and this setup at once… unbelievably good.”

Advanced UT Inspector, SonoInspec

Execution

By deploying HotSense™ HT TOFD, SonoInspec were able to valid the procedure with scans at 33%, 66% and 100% weld fill level, initially at ambient temperatures, and then at elevated temperature (~190 °C / 374 °F). TOFD transducers, 5 MHz, 6 mm with an integrated 50 deg refracted angle wedge were used and were successfully able to:

- At 66% fill, due to the wide weld width, it was possible to detect all indications within the first 40 mm from the ID in the validation blocks (see Figure 1).

- At 100% fill, accurately detect and size both bevel notches, the ID surface notch and all 6 SDH defects in one setup at both ambient temperature and at 185 °C in the validation blocks (see Figure 2).

- When the repairs were executed, the high-temperature TOFD was effective in detecting defects without the need to cool down and bring back up to preheat temperature.