In-service High Temperature UT Inspection Survey by MISTRAS at a U.S. Oil Refinery

In-service, high-temperature corrosion surveying to maximise productivity, safety and plant availability.

Overview

A solution was sought by Mistras, one of the largest suppliers of integrity and inspection services, for an inspection project at a US West Coast oil refinery that involved Ultrasonic Testing (UT) measurements of on stream process pipework and equipment at high temperatures, in the range 350 °F to 700 °F (177 °C -371 °C). UT is a critical activity in the maintenance and up-time of this high value processing unit at the refinery. Measurements were scheduled to be made at a number of identified corrosion monitoring locations (CMLs) during normal production, and this required the use of UT transducers which were able to make high temperature thickness measurements.

The Challenge

Before adopting the Ionix HS582i high temperature UT probe mid-way through the project, the main challenge articulated by the Mistras inspectors at the oil refinery was:

- The time consumed by having to wait for transducers to cool between each reading (duty cycling)

- The ensuing lack of repeatable thickness data

The Solution

Ionix’ HS582i dual element 5 MHz transducers, based on the HotSenseTM ultrasonic platform, were deployed with Mistras’ own standard UT flaw detectors making for immediate implementation.

- The HS582i transducers were chosen for their wide operating temperature range; -67 °F to +1,022 °F (-55 °C to +550 °C), minimising the need for intermittent cooling (duty cycling) and re-calibrating to reduce the inspection time and prevent the need for shutdown or isolation of equipment.

- Increased wear resistance / longer probe life maximized continuous usage and measurement collection

- Probe accessories including high temperature couplants and handles made measurements fast, repeatable and safe.

- Manufactured in compliance with international standards to easily fit directly into the prevailing project UT inspection procedures

- Compatible with commercial high temperature couplants.

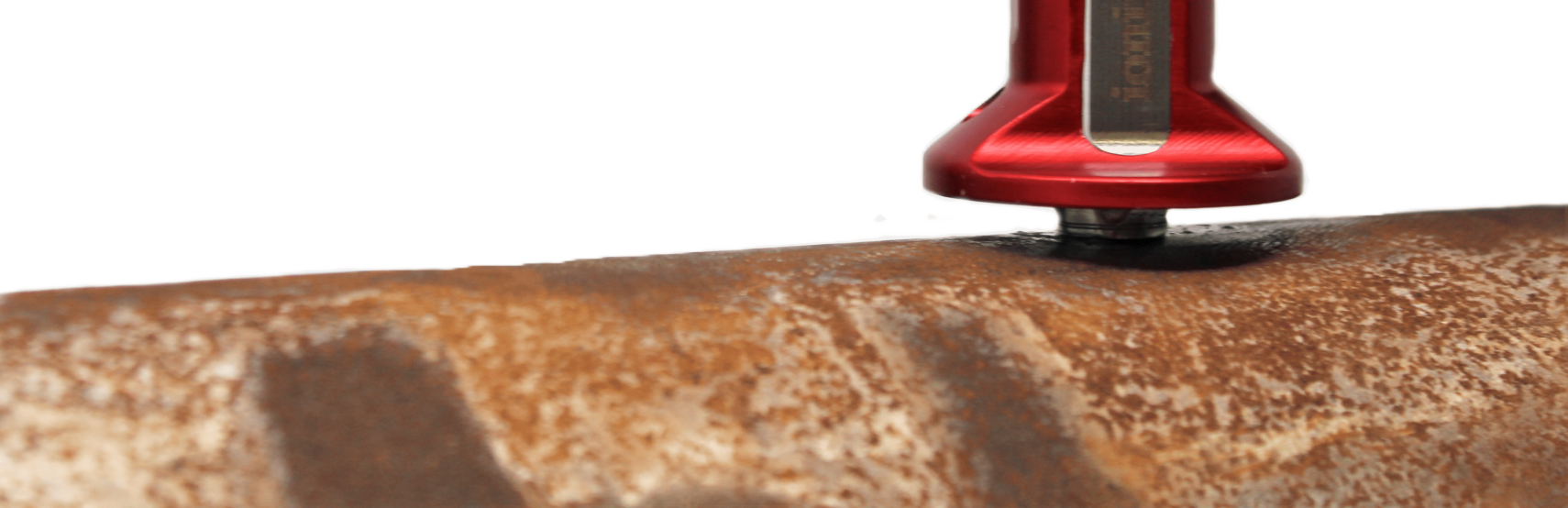

Fig. 1 (Left) Ionix HS582i probe in use at US Oil Refinery by a Mistras Inspector. Pipe temperature readings at time of this inspection were 582°F (305°C). (Right) The thickness measurements were able to be repeated several times with minimal cool down periods.

Execution

- The Ionix HS582i probe was deployed as a replacement for the incumbent transducer. Wall thickness measurements at the designated CMLs were undertaken with the HS582i using conventional UT flaw detectors, and required no additional training or setup.

- Many wall thickness measurements were made with a single probe without causing damage to the probe from heating or excess wear.

Testimonial

“Our Mistras team at the Refinery have been working on projects for process piping ranging from 350°F to 700°F. It was very time consuming having to wait for our transducers to cool between each reading and not getting repeatable thickness data. We started using the Ionix HS582i 5MHz transducer and it made a significant difference in time between readings and accuracy. In conclusion, the Ionix transducer worked exactly as advertised for the higher range that we utilized it on .”