Non-Invasive Thickness & Corrosion Monitoring

We are the extreme environment experts. We enable plant digitalisation and the realisation of Industrial IOT solutions. We combine our market leading HotSenseTM sensors with the best-fit data collection system to provide a complete monitoring solution to deliver key asset integrity data, meeting cost, HSE, and operational targets across refining, oil & gas, energy, nuclear and process sectors

Start monitoring your assets with HotSenseTM to increase plant productivity:

- Remove variables caused by periodic inspection process.

- Provide more frequent data, with no increase in costs to improve RBI data / deliverable.

- Get more actuate data to feed your FFS studies.

- Remove conservatism from your asset retirement planning.

- Enable use of lower cost feedstock options

- Confirm effectiveness of corrosion inhibitors.

- Enable better data to make informed decisions around change management:

- Production increases

- Shutdown planning

ADVANTAGES

OPTIMISED

- Increase what can be monitored – HotSenseTM transducers allow for deployment directly to hot assets for measurements from -55˚C to + 550˚C (-67 to 1022 deg F).

- Increase Safety – Intrinsically safe and certified for deployment across your business (FM Cl 1 Dv 1-2, ATEX & IECEx Zone 0-1)

- Reduced maintenance – Transducers and node may be positioned independently to allow for ease of access for battery change – no need for scaffolding or rope access. Service packages available.

- Cost efficient – Multiple transducers per measurement node to minimise batteries.

- Improved network stability – Nodes positioned to maximise wireless signal.

- Maximise flexibility – Flexible and robust deployment and data management options

AUTOMATED

- Automated – thickness measurements, temperature measurements and corrosion rates transmitted directly to your control room.

- Security – Advanced data management software on local server or data direct to you DCS and PIMS – data never leaves your site.

- Configurable alarms – Robust and reliable measurements for determination of wall loss rates & absolute thickness.

- Inhouse data access – Make data available to both maintenance and operations teams to better optimise plant productivity.

- Built-in calibration – Measurements may be validated using HotSenseTM transducer integrated calibration block.

WIRELESS

- Fully WirelessHART certified and compliant for integration into your operations.

- Remote measurement configuration and maintenance.

- Battery life is transmitted allowing maintenance and data collection scheduling.

TECHNICAL DETAILS

SURVEY, INSTALLATION, COMMISSIONING AND SUPPORT

Ionix, with our system and global or local service partners can provide planning and pre-installation surveys, as well as ongoing system service and data health packages tailored to your requirements.

DATA & SYSTEM HEALTH CHECK

Ionix understand that the project doesn’t finish at installation. To support the operation of your monitoring solution and continual improvement in data collection, we provide ongoing System Service packages tailored to a client’s requirements.

STANDARD SYSTEM SPECIFICATION

| Parameter | Value |

|---|---|

| MEASUREMENT | |

| Temperature | -55 ºC to +550 ºC |

| Resolution | 0.0025 mm** |

| Detectable Wall Loss Rate | > 0.025 mm / yr |

| Thickness range | See transducers |

| Temperature Compensation | Automated when thermocouple installed |

| SYSTEM | |

| Channel per node | 1 - 4 |

| Thermocouples | Optional. Up to 4 with HotSense™ 380 and UHT. Up to 2 with HotSense™ DE |

| Certification | IS/Class I, Division 1, Groups A/B/C/D; Ex ia IIC T4 for -55°C ≤ Ta ≤ +55°C; |

| Rating | IP66 |

| Battery type | Lithium D |

| Battery life | Up to 5+ years |

| ** Subject to pipe thickness and temperature. | |

| Parameter | Value |

|---|---|

| WIRELESS | |

| Communication Protocol | WirelessHART (IEC 62591) |

| Security | 128-bit AES Security |

| Maximum units per gateway | 25, 100, 200 depending on spec |

| Maximum total number of devices | 30,000 |

| Data collection frequency | 1 hour + |

| Single hop range | >100m LOS |

| SOFTWARE | |

| Data output | Thickness, wall loss rate (short & long), temperature, battery, A-scan |

| Export | Whole database or subset, .csv |

| Data storage and access | Local server, DCS, PIMS etc |

| Protocol | EtherNet/IP, Modbus RTU/TCP, OPC, HART-IP |

| Diagnostics | Remote diagnostics of transducer, node, network and measurement |

| Calibration | Automated |

| Battery remaining life | As a function of usage or voltage |

STANDARD TRANSDUCER & DEPLOYMENT SPECIFICATION

| PARAMETER | VALUE | VALUE | VALUE |

|---|---|---|---|

| HOTSENSE™ SINGLE ELEMENT | BONDED SINGLE ELEMENT* | DUAL ELEMENT |

|

| Frequency | 3 MHz | 5 MHz | 5 MHz |

| Application | All | Low temperature vessels | Low temperature, thin walled |

| Thickness Range | >2.5 mm | >2.5mm | >1mm |

| Continuous temperature range | -55 °C to + 380 °C 550 °C by request | -40 °C to +200 °C | -55 °C to +150 °C |

| Deployment options | Straps, welded studs | Epoxy | Straps + epoxy |

| Cable length | 0.325 - 2.5 m high temperature + 2-15 m flex | 1.5 m standard (3 or 6 m by request) | 2-15m |

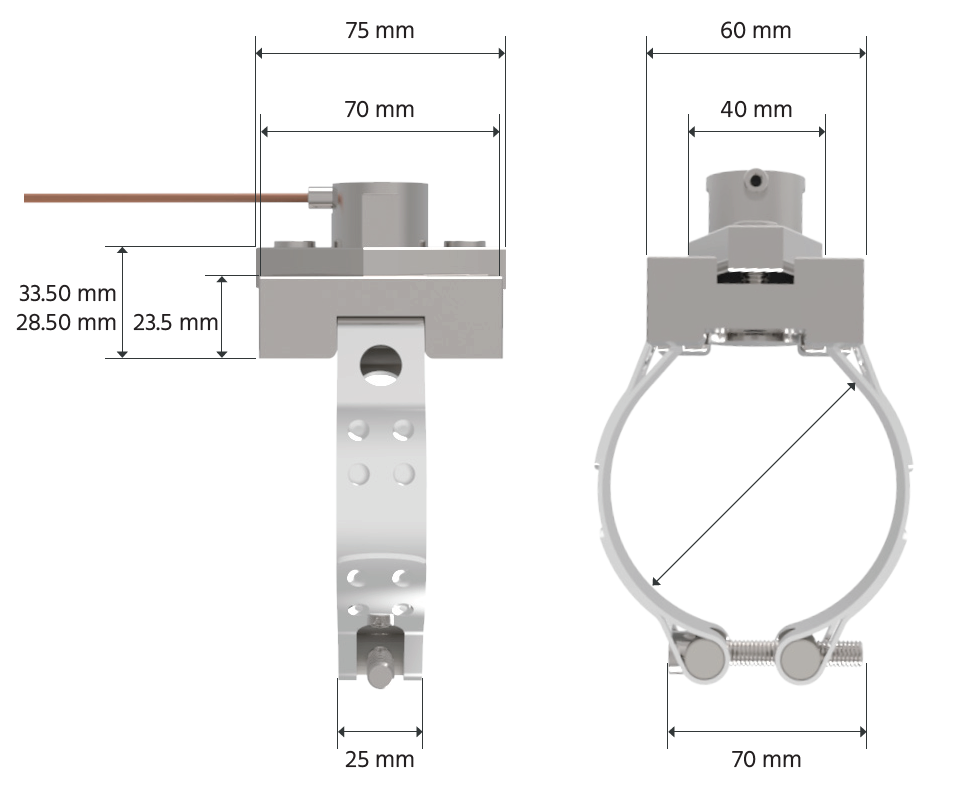

| PARAMETER | VALUE | VARIABLES |

|---|---|---|

| Material Mounts/Clamps | 316 Stainless Steel | - |

| Standard Clamp Sizes for Pipes | NPS 2” to NPS 16” | Other sizes available via special request |

| Standard Stud for Vessels | M8 x (40 - 60 mm) | Other sizes available via special request |

| Standard Stud Spacing | 52.5 +/- 5mm | Other sizes available via special request |

| Stud Torque Resistance | >20 N.m | - |

| Total Mass (Transducer + deployment) | 1.0 - 1.4 kg | Dependent on deployment method |

CASE STUDIES

Online Wall Thickness Monitoring

Refinery wide HotSenseTM

deployment to reduce risk, increase safety and maximise data availability