OEM Sensors and Solutions

Want the benefits of our HPZ powered HotSense platform in your solution?

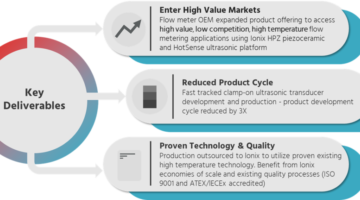

Expand your application range or enter new markets by integrating our high-performance piezo and extreme environment transducer platform to provide increase your capability.

We already white-label sensors and assemblies for use in applications across flow metering, level, temperature, gas void, corrosion/wear, and vibration sensing.

Ionix HPZ™ has a range of key properties that make it an ideal piezoelectric material to sit at the core of your sensors, actuators and devices to enhance ruggedization, increase the operating temperature and maximise reliability.

OUR TECHNOLOGY

- Built on the award winning HotSense™ ultrasonic platform powered by the proprietary Ionix HPZ piezoceramic.

- High sensitivity for a range of electro-mechanical sensors including ultrasonic, vibration and acoustic emission, without the need for amplification.

- Proven performance across -200 to +600 °C [-328 to +1,112 °F]. Wide ambient operating temperature range for on-stream processes from liquid nitrogen to boiler tubes.

- Robust packaging and stable signals for maximum reliability and repeatability in critical applications, including nuclear, aerospace and automotive.

- Highly tuneable for easy integration into your current and future electronics, including Ex and other certification.

Current OEM Sensor Solutions

- Intrinsically safe, ultrasonic flare gas metering transducers, for operation -200 to +350 °C with a 4000:1 turndown ratio, integrated in to a global flare gas metering supplier.

- Non-intrusive, intrinsically safe, ultrasonic liquid flow metering transducers up to +380 °C with mechanical deployment compatible with a range of ultrasonic flow metering systems provided by blue chip industrial automation providers.

- Non-intrusive, shear/lamb wave ultrasonic steam flow metering transducers with increased sensitivity for direct implementation to commercial metering systems.

- Air coupled ultrasonic transducers for in-process humidity and volumetric temperature measurements up to 420 °C for commercial automotive manufacturer.

- Permanently installed transducers using multi-element arrays for volumetric weld defect monitoring in nuclear environments.

- Integrated ultrasonic sensors for EV wear monitoring, and high-performance drive train speed and location sensing for a high-performance automotive engine manufacturer.

- Acoustic emission sensors (50 to 400 kHz) for industrial gas turbine engine management multi-national.

- Vibration monitoring accelerometers for asset monitoring across a wide operating temperature range -55 to +300 °C in energy sectors.

- High reliability and precision level/range sensing in kerosene operated hydraulic actuators.

- Submerged, high-temperature (+600 °C) condition monitoring of molten salts and metals for global energy plant operators