In-process weld repair of ammonia converter with HotSense TOFD

Real-time evaluation of weld fills during repair of an ammonia converter, using high-temperature TOFD examination.

Case Studies, Inspection, News, TOFD, TOFD Case Study asset integrity, Case Study, downstream, HotSense UT, Inspection, NDT, Oil & Gas

Real-time evaluation of weld fills during repair of an ammonia converter, using high-temperature TOFD examination.

Application Insight: Alkylation, HotSense, Monitoring application note, Monitoring case study, News Alkylation, asset integrity, downstream, HotSense, Inspection, NDT, Oil & Gas

Non-invasive, corrosion trending with wireless ultrasonic probes and monitoring system to maximise throughput and run length of variable feedstocks.

HotSense_UT, Inspection application note, Inspection case study, News asset integrity, HotSense, Inspection, NDT, Oil & Gas, UAV

Significant corrosion can occur in stacks and flares due to the presence of acidic compounds in the gases, in the presence of moisture and at elevated temperatures.

A refinery operator sought to inspect their stacks, onstream at high-temperatures using aerial drone platform with a HotSense UT payload to determine fitness for service.

Read our latest case study that highlights why on-stream inspection requires robust transducers with high sensitivity and temperature resilience , and which can reliably make high-temperature wall thickness measurements to prevent the need for shutdown and maintain productivity while reducing costs.

HotSense, News asset integrity, Corrosion Monitoring, HotSense, Inspection, NDT, Oil & Gas

A solution was sought by a leading inspection services term contractor for one of their clients operating a large petrochemical refinery to conduct in-service corrosion surveys across their facilities infrastructure. UT is critical to the plant’s needs and is used extensively for corrosion surveys, but the refinery includes assets with surface temperatures from 120°C to over 350 °C including gas boilers, pressure vessels and piping.

Read our latest case study that highlights why on-stream inspection requires transducers with efficient acoustic coupling, and which can reliably make high-temperature wall thickness measurements to prevent the need for unplanned shutdown and maintain productivity while reducing costs.

HotSense, Monitoring Corrosion Monitoring, Gas Void Monitoring, HotSense, Monitoring, Nuclear, Oil & Gas

The ability to detect gas voids in cooling water lines was required by one of the largest electric power holding companies in the US, generating electricity from mixed sources, including 6 nuclear plants. Find out ho the Ionix solution helped.

Inspection case study, TOFD Case Study Corrosion Monitoring Techniques and Methods, HotSense, Oil & Gas, TOFD

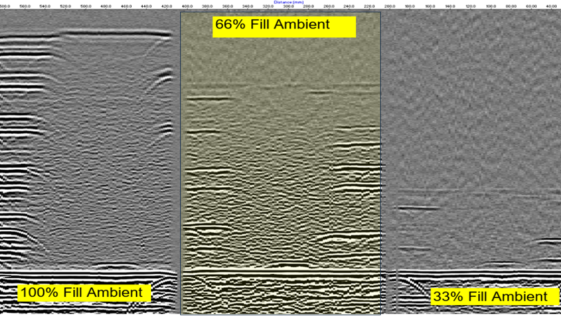

Ultrasonic time-of-flight diffraction (TOFD) is a popular method widely used in petrochemical, energy and other industries for the in-service detection and characterisation of weld defects such as root corrosion, porosity, inclusions, and cracks.

Application Insight: Buried Tailing Lines, Application Insights, HotSense, Monitoring, News AI Caliperay, AI FDLK, AI HotSense 380, AI HotSense DE, AI Measurement Hub, Buried Tailing Lines, Corrosion Monitoring, HotSense, Inspection, Mining, Oil & Gas, Wear Monitoring

HotSense™ is a non-invasive ultrasonic wear monitoring solution born out of the extreme environments of the energy sector:

For users of critical components or linings susceptible to wear;

Who want to always know the remaining life of their assets;

So that they can shorten outages to maximise availability and reduce outage costs.

Unlike manual inspection and invasive technologies, HotSense™ provides direct wall thickness trending loss and detection of changes to predict maintenance intervals whilst plant is running.

HotSense, Monitoring, Monitoring Datasheet, Product Datasheet Corrosion Monitoring, Corrosion Monitoring Techniques and Methods, FDLK, Field Data Logging Kit, HotSense, NDT, Nuclear, Oil & Gas

HotSense™ Field Data Logging

Kit (FDLK) for automated

ultrasonic measurement

logging. For the rapid deployment and management of WirelessHART ultrasonic projects and data

collection.

Application Insight: Buried Tailing Lines, Application Insights, HotSense, Monitoring, News AI Caliperay, AI FDLK, AI HotSense DE, AI Measurement Hub, Buried Tailing Lines, Corrosion Monitoring, HotSense, Inspection, Oil & Gas

Ionix EchoCorr™ is a non-invasive ultrasonic thickness monitoring system suitable for the mining, chemical and oil and gas industries to optimise the management and maintenance of buried tailing lines. Explore this Application Note for more information.