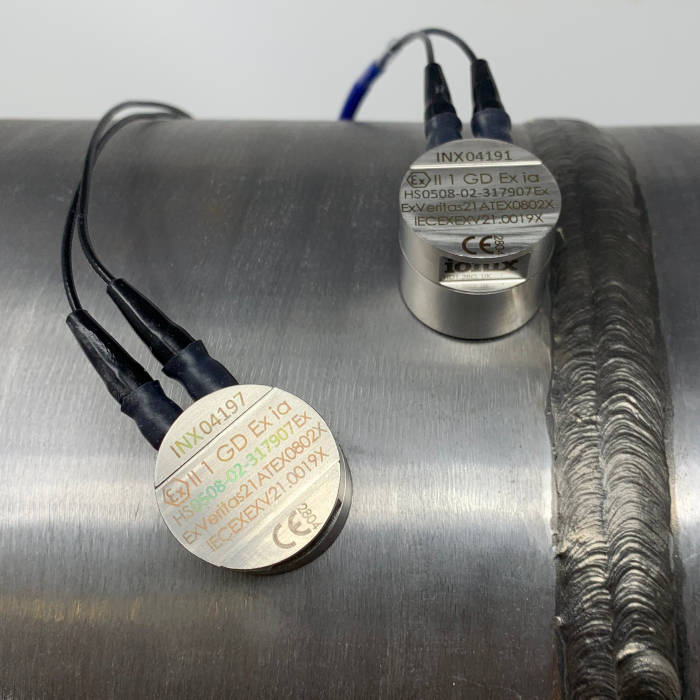

HotSense™ 150 Dual Element

Reduce the cost and complexity of on-stream ultrasonic monitoring

Dual element ultrasonic transducer for on-stream thickness, corrosion and erosion monitoring for use in applications across refining, oil & gas, energy, nuclear, aerospace, and process sectors.

OUR TECHNOLOGY

- Low-cost dual element ultrasonic monitoring sensors for widespread distribution.

- Through coating measurements without removal of protective coatings.

- Installation on all sizes of pipes and vessels.

- Built on the award winning HotSense™ ultrasonic platform next generation sensors powered by the proprietary Ionix HPZ piezoceramic.

- -55 to +150 °C [-67 to +302 °F] continuous measurement temperature range.

- Permanent or semi-permanent installation in extreme or hazardous environments.

- Intrinsically safe certified to Zone 0.

- Manual or automated data collection.

ADVANTAGES

- Produce better wall loss data and trends with installed UT probes.

- Low cost dual element ultrasonic monitoring sensors for widespread distribution and area coverage.

- Through coating measurements without removal of protective coatings.

- Installation on all sizes of pipes and vessels.

- Dual element configuration for increased sensitivity of pitting damage mechanisms .

- Built on the award winning HotSense™ ultrasonic platform. Next generation sensors powered by the proprietary Ionix HPZ piezoceramic.

- -55 to +150 °C [-67 to +302 °F] continuous measurement temperature range.

- Permanent or semi-permanent installation in extreme or hazardous environments.

- Intrinsically safe certified to Zone 0.

- Manual or automated data collection.

Deployment Flexibility

- Deploy on to live assets without shutdown or isolation.

- Options for vessels and pipes NPS 52″ and above.

- Integrated magnetic fixing for ease of installation on ferrous assets.

- Epoxy fixings for large pipes and vessels.

- Universal strap fixing for small pipe diameters and semi-permanent installation.

- Deploy around the circumference, spine or survey grid of piping.

Solution Benefits

- Fixed UT sensors provide increased measurement precision and collection frequency for reliable and real-time corrosion trending.

- Optimise Asset Integrity and Performance Management (AIM/APM) programmes with accurate and reliable wall loss data.

- Reduce operational costs and maximise production margins.

- Data collection using standard UT flaw detectors with Measurement Hub.

- Autonomous data collection and data direct to control centre with WirelessHART Caliperay.

APPLICATION INSIGHTS

TECHNICAL DETAILS

- Wide temperate range installed monitoring probe with deployment flexibility without coating removal.

- Dual element, compression wave.

- Accurate and precise thickness measurements from fixed installed probes.

- Detect and trend wall loss rates with increased precision.

- Flexible installation and coupling solutions for deployment on any asset. Magnetic fixtures support installation on ferrous assets with fixation and coupling achieved with epoxy or polymer pad and strap.

- 30mm probe diameter allows for deployment in close proximity on grids or circumferentially around an asset.

- Installation without coating removal is ideal for upstream applications. Measurements may be made through coatings.

SYSTEM COMPATIBILITY

- For use with HotSense™ Measurement Hub manual and CALIPERAY automated monitoring solutions.

- Compatible with industry standard UT flaw detectors and thickness gauges.

CASE STUDIES

APPLICATION NOTES

TRANSDUCER & DEPLOYMENT SPECIFICATIONS

| PARAMETER | VALUE | VARIABLES |

|---|---|---|

| Strap free deployment | ||

| Applications | Vessels, larger pipe diameters, grids | Optional retention lanyard |

| Fixing | Magnetic & epoxy adhesive | Other sizes available via special request |

| Coupling | Epoxy | |

| Cure time | Minimum of 1 hour at 150 °C | Cure in-service |

| Diameters | >NPS 3" | Ideal for vessels |

| Installation on coatings | Yes | |

| Semi-permanent deployment | ||

| Applications | Installations where the probes may be moved frequently | |

| Fixing | Magnet & universal steel strap | Optional retention lanyard |

| Coupling | Solid couplant | |

| Diameters | NPS 2" to 36" | |

| Installation on coatings | Yes | |

Typical Ultrasonic Response