Ultrasonic Testing Transducers

Reduce inspection time with no duty cycling and robust calibration

Dual element ultrasonic transducers for on-stream, thickness, corrosion and erosion surveys with a wide operating temperature for use in applications across refining, oil & gas, energy, nuclear, aerospace, and process sectors.

OUR TECHNOLOGY

- Built on the award winning HotSense™ ultrasonic platform powered by the proprietary Ionix HPZ piezoceramic.

- Dual element thickness gauging transducers in a range of frequencies and tip sizes for use in extreme environments.

- -55 to +550 °C [-67 to +1,022 °F] wide measurement temperature range for all in-service assets.

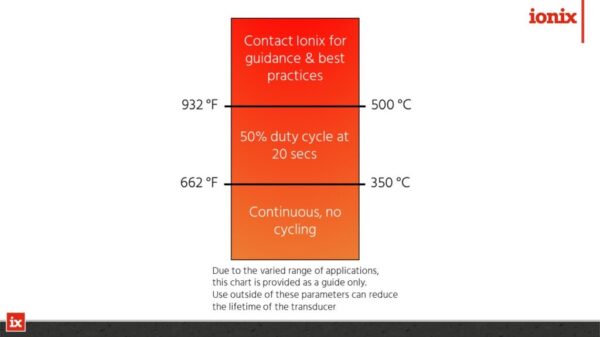

- No cooling required up to 350 °C / 662 °F. Increase your productivity between calibrations and reduce duty cycling.

- Stable signal for maximum reliability and repeatability.

- Enhanced wear resistance for the most extreme environments and applications.

ADVANTAGES

- Make on-stream wall thickness measurements on hot assets, in-service, without the need to shut down or isolate.

- Measure remaining wall thicknesses from 1 to 500 mm thick with compliant thickness gauges.

- Compatible with recommended high-temperature ultrasonic couplants.

- Robust stainless-steel construction, and large tip options for scanning.

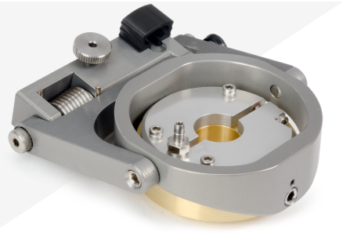

- Range of accessories available, including port inspection wand, safety guards and scanner probe holders for the highest-temperature applications.

TECHNICAL DETAILS

- Measure remaining wall thickness from 1 to 500 mm with compliant thickness gauges on hot assets, in-service, without shutdown or isolation.

- Better data from easier and more accurate calibration at asset temperature.

- 2X increased wear resistance for the most extreme environments and applications including scanning and corrosion mapping.

- Range of accessories available, including port inspection wand and safety guards for the most extreme temperatures.

- Compatible with industry standard ultrasonic gauges and flaw detectors.

- Range of frequencies available to penetrate thicker or scattering materials.

- Compliant to ISO 22232-2 and ASTM E1065 to meet existing asset integrity UT procedures.

CASE STUDIES

TRANSDUCER SPECIFICATION

| Product Code | Description | Range in Steel | Focus |

|---|---|---|---|

| HS 582i | 5 MHz, 8 mm diameter/2 active element Tip diameter 11 mm / [0.434"] | 2 to 50 mm [0.08 to 2"] | 10 mm [0.39"] |

| HS 5122i | 5 MHz, 12 mm diameter/2 active element Tip diameter 18 mm / [0.708"] | 2.5 to 250 mm [0.98 to 9.84"] | 20 mm [0.79"] |

| HS 2122i | 2.5 MHz, 12 mm diameter/2 active element Tip diameter 18 mm / [0.708"] | 10 to 500 mm [0.39 to 19.7"] | 30 mm [1.18"] |

*See duty cycle chart for use. Requires compatible couplant.

Acoustic characteristics certificate of conformity supplied with each unit.

For other specification requirements please contact our sales team.

MEASUREMENT PERFORMANCE

MASTERCLASS IN HIGH-TEMPERATURE ULTRASONIC TESTING

Develop your skills and those of your team with the Ionix Masterclass in High-Temperature Ultrasonic Testing (UT) for Thickness, Corrosion and Erosion Surveys.

Delivered at your facility, virtually, or at the Ionix offices in Huddersfield, UK.

The Masterclass includes:

- Safety, standards and best practices

- High-temperature damage mechanisms

- Influences of temperature on material properties

- Main sources of error with UT

- Calibration procedures

- Procedure Template

- Live demos

USER GUIDANCE

HOTSENSE™ UT FAQ

If you have any further questions or require technical support, please contact Ionix at support@ionix.at