Automated Wireless Ultrasound for on-stream corrosion, erosion and wear monitoring

Track wall loss rates, detect changes and see into the future to optimise operations and reduce outages

Non-invasive, automated and wireless ultrasonic monitoring solutions for applications across refining, oil & gas, energy, nuclear and process sectors.

OUR TECHNOLOGY

Start monitoring your assets with HotSense™ to increase plant productivity:

- Make real-time, data driven decisions. Improve process parameters to increase profitability, up-time and efficiency.

- Increase safety, defer maintenance and improve turnaround schedules with actionable asset insights.

- Provide more frequent data, with no increase in costs to improve RBI data / deliverable.

- Remove variables caused by periodic inspection process.

- Get more actuate data to feed your FFS studies.

- Remove conservatism from your asset retirement planning.

- Enable use of lower cost feedstock options.

- Confirm effectiveness of corrosion inhibitors.

ADVANTAGES

CALIPERAY

- Automated non-invasive corrosion, erosion and wear monitoring.

- High precision HotSense™ probes for range of deployment.

- -200 to +550 °C (-328 to +1022 °F).

- On-stream installation on pipes or vessels.

- Low profile under insulation or in confined spaces.

- High frequency data collection direct to server or control room.

- Automated, WirelessHART mesh, Battery Powered, Ex.

TRENDING

- Track wall loss rates, detect changes and see into the future.

- Understand current wall loss rates to feed maintenance planning.

- Detect changes and relate to process conditions.

- Extrapolate trends to predict impact of changes on asset condition.

- Optimise Decision Making.

- Predict maintenance intervals and avoid un-planned shutdowns.

- Optimise process conditions to maximise productivity.

DATA COLLECTION

- Get trending data now!

- Data collection on-premise or remote server.

- No internet or cloud required (cloud option available).

- Fully contained Field Deployment Kit can be deployed in under an hour.

- Data in standalone system or integrated into control systems.

- Implement alongside current inspections.

- Complements traditional NDT inspections.

- Integrate with current integrity data.

APPLICATION INSIGHTS

TECHNICAL DETAILS

SURVEY, INSTALLATION, COMMISSIONING AND SUPPORT

Ionix, with our certified global, local service partners can provide planning and pre-installation surveys, as well as ongoing system service and data health packages tailored to your requirements.

DATA & SYSTEM HEALTH CHECK

Ionix understand that the project doesn’t finish at installation. To support the operation of your monitoring solution and continual improvement in data collection, we provide ongoing System Service packages tailored to your site requirements.

CASE STUDIES

STANDARD SYSTEM SPECIFICATION

| Parameter | Value |

|---|---|

| MEASUREMENT | |

| Temperature | -55 ºC to +550 ºC |

| Resolution | 0.0025 mm** |

| Detectable Wall Loss Rate | > 0.025 mm / yr |

| Thickness range | See transducers |

| Temperature Compensation | Automated when thermocouple installed |

| SYSTEM | |

| Channel per node | 1 - 4 |

| Thermocouples | Optional. Up to 4 with HotSense™ 380 and UHT. Up to 2 with HotSense™ DE |

| Certification | IS/Class I, Division 1, Groups A/B/C/D; Ex ia IIC T4 for -55°C ≤ Ta ≤ +55°C; |

| Rating | IP66 |

| Battery type | Lithium D |

| Battery life | Up to 5+ years |

| ** Subject to pipe thickness and temperature. | |

| Parameter | Value |

|---|---|

| WIRELESS | |

| Communication Protocol | WirelessHART (IEC 62591) |

| Security | 128-bit AES Security |

| Maximum units per gateway | 25, 100, 200 depending on spec |

| Maximum total number of devices | 30,000 |

| Data collection frequency | 1 hour + |

| Single hop range | >100m LOS |

| SOFTWARE | |

| Data output | Thickness, wall loss rate (short & long), temperature, battery, A-scan |

| Export | Whole database or subset, .csv |

| Data storage and access | Local server, DCS, PIMS etc |

| Protocol | EtherNet/IP, Modbus RTU/TCP, OPC, HART-IP |

| Diagnostics | Remote diagnostics of transducer, node, network and measurement |

| Calibration | Automated |

| Battery remaining life | As a function of usage or voltage |

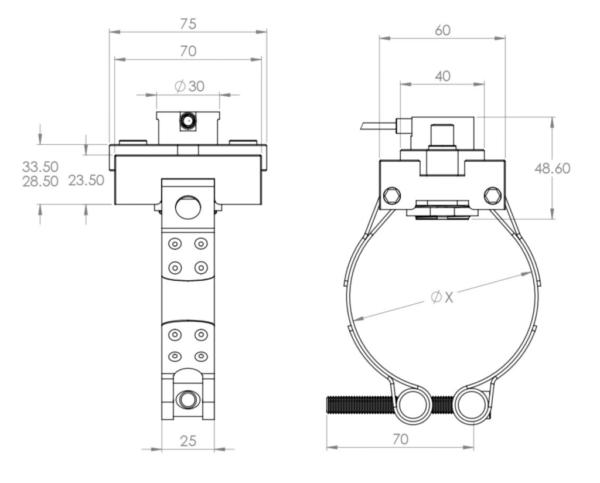

STANDARD TRANSDUCER SPECIFICATION

| HotSense™ 150 View Product | HotSense™ 380 View Product | HotSense™ UHT View Product | |

|---|---|---|---|

| Frequency | 5 MHz | 3.25 MHz | 3.25 MHz |

| Application | Standard temperatures, measurements through coatings, large pipes and vessels | All | All |

| Thickness Range | >1 mm | 2.5 mm - 22.5 mm | >2.5 - 72.5 mm |

| Continuous Temperature Range | -55 °C to +150 °C | 400 °C | 550 °C |

| Deployment Options | Magnetic mount + Epoxy or strap + rubber couplant | Straps or welded stud | Straps or welded stud |

| Cable Length | 2 or 15 m flex | 1 m high temperature + 2 or 15 m flex | 1 m high temperature + 2 or 15 m flex |