HotSense™ 380

Minimise operational risk and maximise productivity with enhanced asset intelligence.

Ultrasonic transducers for 0-degree measurements ideal for thickness, corrosion and erosion monitoring for use in applications across refining, oil & gas, energy, nuclear, aerospace, and process sectors.

OUR TECHNOLOGY

- The original, truly high-temperature transducer powered by the Ionix HPZ piezo-ceramics.

- Permanent or temporary installation in the most extreme environments.

- -200 to +550 °C [-328 to +1,022 °F] continuous measurement temperature range.

- On-stream installation and calibration with integrated reference block for reliable, traceable, data.

- Highest sensitivity in class for highest accuracy and precision in the most challenging installations.

- Intrinsically safe certified to Zone 0 for use in the most hazardous locations.

ADVANTAGES

- Wide continuous operating temperature range from -55 °C to +550 °C for an extensive variety of online monitoring requirements.

- Complement inspections and improve repeatability and accuracy with fixed transducers installed directly onto assets.

- Know the status of your assets and manage maintenance programs and budgets more efficiently through informed resource allocation and repairs only when required.

- Advanced pipeline corrosion monitoring technology.

APPLICATION INSIGHTS

TECHNICAL DETAILS

- High temperature capable piezoelectric element and transducer components designed for permanent installation in extreme environments.

- Single element, compression wave, pulse-echo operation.

- Accurate and precise thickness measurements with resolution from 0.01-0.1mm.

- Wall loss resolution of 25 µm.

- Stable and secure fixation methods available via clamping or bonding to a structure for permanent installation even at extreme temperatures.

- Compact integrated delay line footprint allows area coverage with high resolution.

- Integrated delay line provides near surface resolution and simple calibration at any temperature.

CASE STUDIES

APPLICATION NOTES

TRANSDUCER SPECIFICATIONS

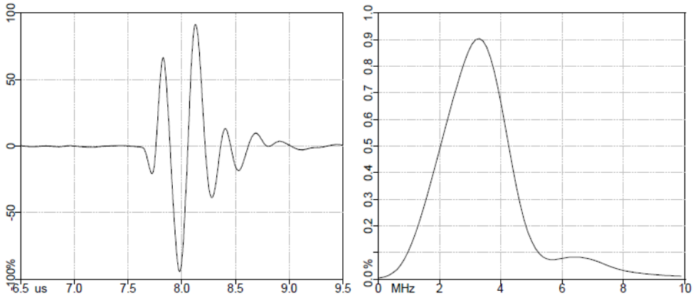

Typical Ultrasonic Response